Quality products that pack a punch

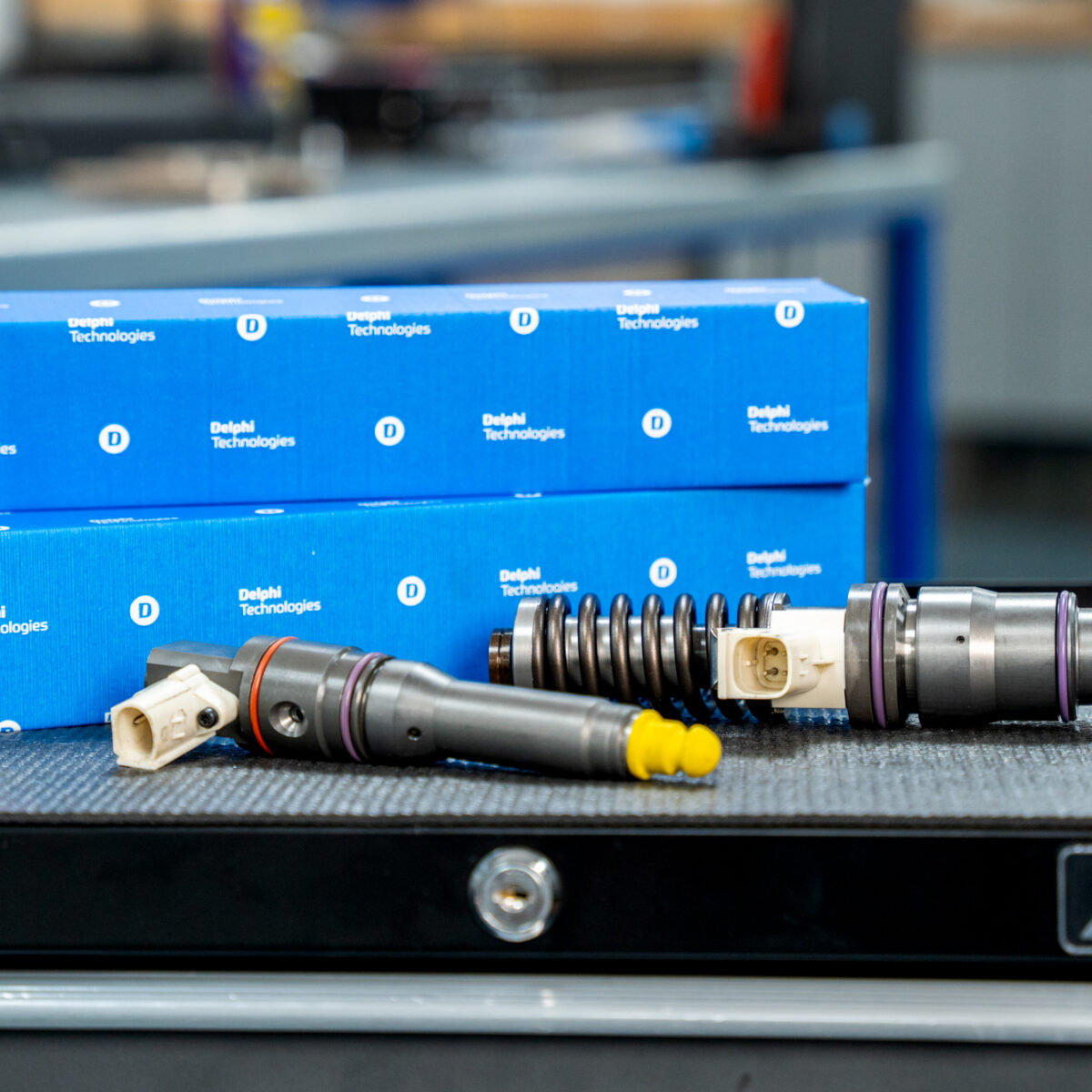

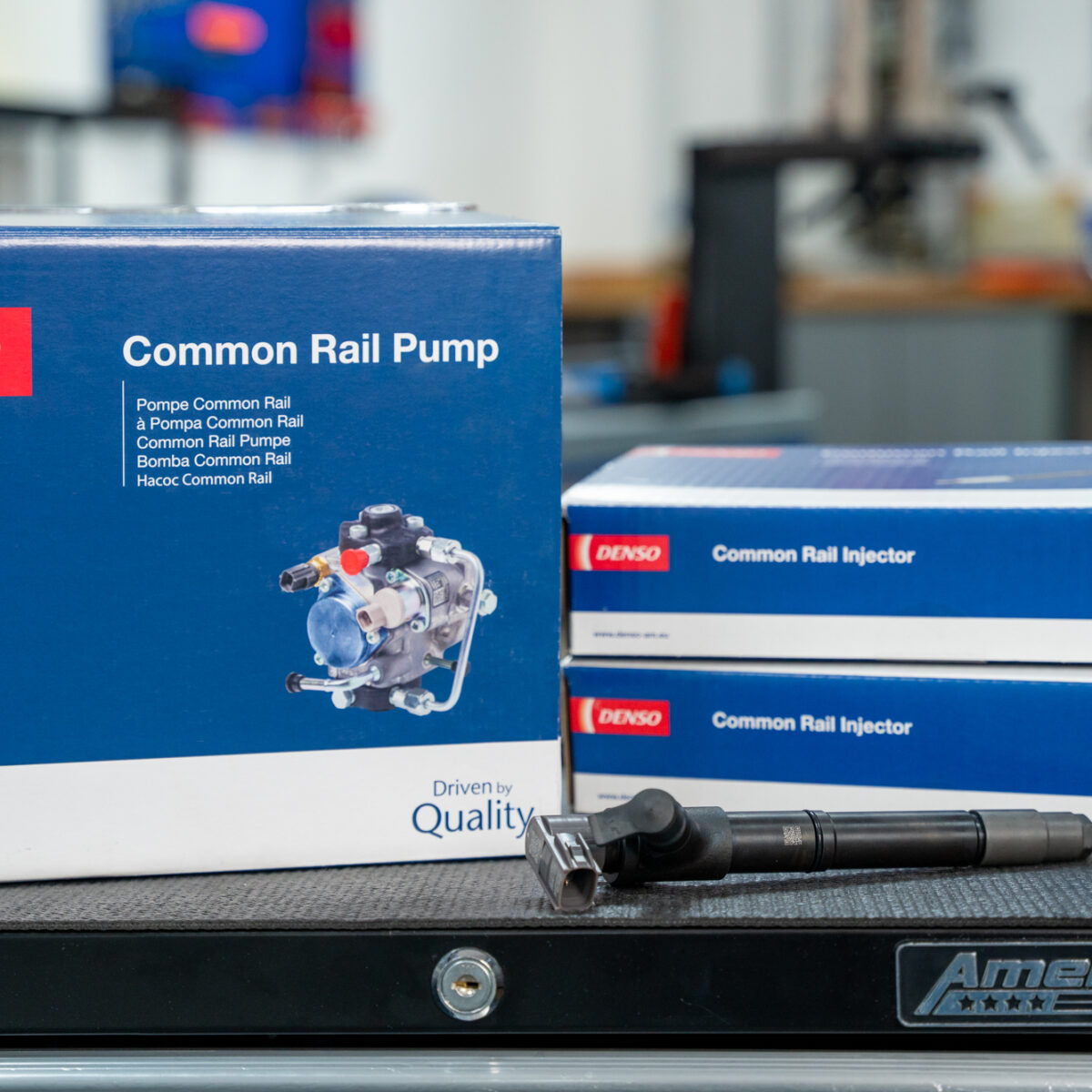

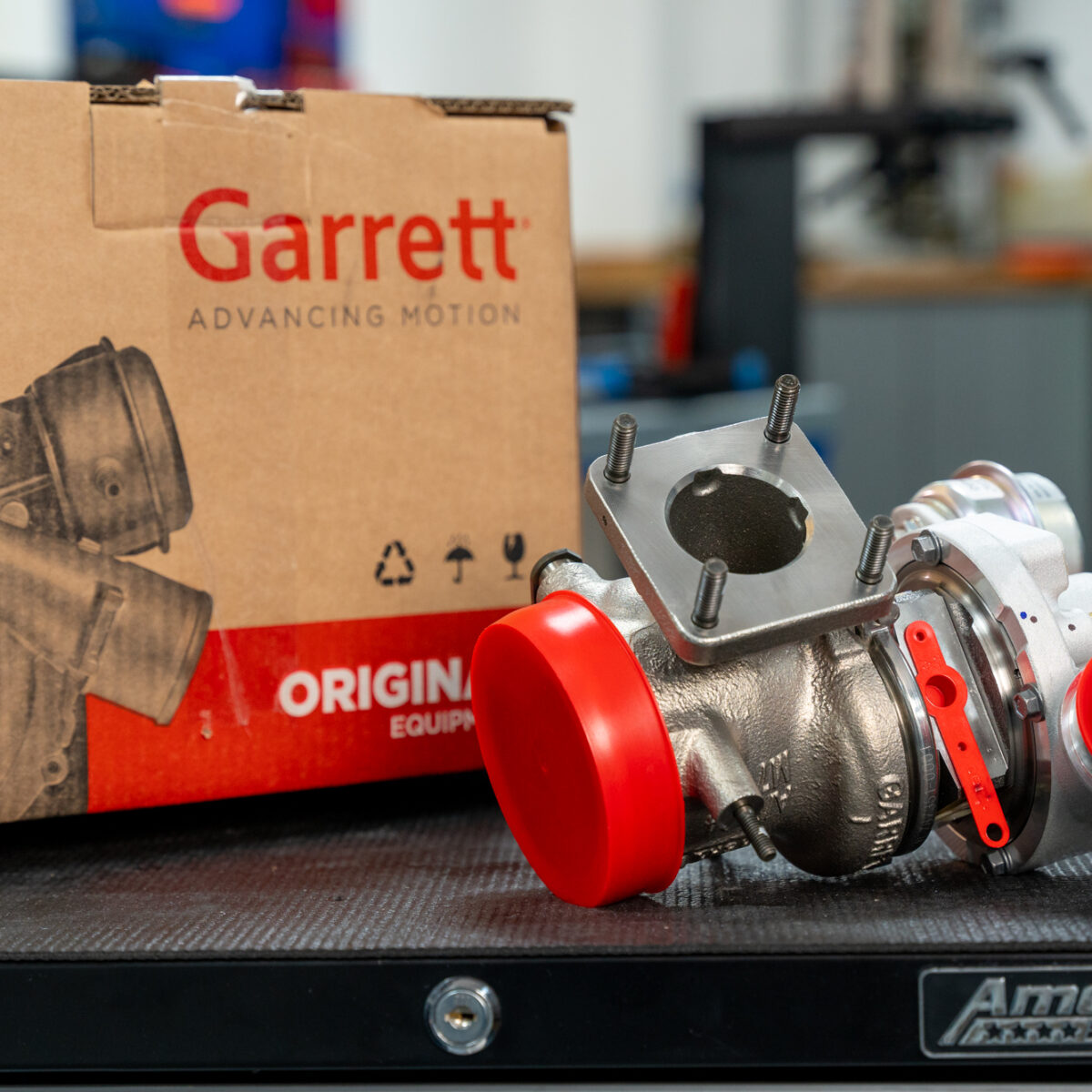

In addition to our range of industry-leading services, we can also provide a wide range of products and components, including pumps, auxiliary parts, turbos, and our very own diesel additive, Diesel Rhino. All parts are hand-picked by our expert team of engineers and specialists before being shipped to you for your own installation and fitting.

Check out a selection of the types of models we stock below. If you have any specific needs or don’t see the model or type of product you need, get in touch. We have access to thousands of parts which we can ship in just a few days (stock permitting). Contact us today to learn more about our available stock and pricing.